Products Offered at Raol Agencies

Our company has earned a reputation in a time span of four years because of the ultimate quality sewing machine parts we have been supplying to clients in market. All the products are imported from China, keeping in mind that they are the best in terms of performance. We provide all sort of sewing machine spare part solutions to clients at the most competitive prices. Our range include: Spare parts for JACK, JUKI, YAMATO, PEGASUS, SIRUBA, JAKI, YOTON, FEIYUE and also needle plates, Embroidery Machines industrial sewing machine tube lights, knife (all types), folders for sewing machines, gauge sets, hook sets, bobbin case and bobbins.

We offer a comprehensive range of industrial machines for the garment industry, covering the entire spectrum from cutting to finishing sections. Our team specializes in the manufacturing and distribution of embroidery machines, as well as industrial and embroidery machine spare parts. We also provide an extensive selection of related general consumables, including electronic cards, electrical items, and motors. With our focus on quality and customer satisfaction, we ensure that all our products meet the highest industry standards. Whether you need a cutting machine, embroidery equipment, or any other garment manufacturing components, we have you covered. Trust us to deliver reliable solutions for your industrial machine requirements.

We are proud to present a comprehensive selection of products available in our inventory of Industrial garment machines. Our offerings include cutting machines, embroidery machines, sewing machines, buttonhole machines, bartack machines, fusing machines, pressing machines, and many more. Additionally, we provide a range of spare parts and accessories for these machines. From straight knife cutting machines to multi-head embroidery machines, our collection covers various needs in the garment industry. We prioritize delivering high-quality and reliable products that cater to the diverse requirements of our customers. With our extensive range of industrial garment machines, we are confident that you will find the perfect solutions to enhance your production processes and achieve exceptional outcomes.

Cutting Section:

Straight Knife Cutting Machines:

The garment industry relies extensively on straight knife cutting machines for precise and efficient fabric cutting. Moreover, these machines employ a straight, oscillating blade that swiftly slices through fabric layers. Additionally, with adjustable cutting speeds and blade sizes, they accommodate various fabric types and thicknesses. Furthermore, straight knife cutting machines offer versatility, enabling straight-line cutting as well as curves and angles. Moreover, equipped with sharp and durable blades, they deliver clean and precise cuts, minimizing fabric wastage. Furthermore, these machines play a pivotal role in ensuring consistent and top-quality garment production. Additionally, they boost productivity and streamline the cutting process throughout the garment manufacturing workflow. Ultimately, their significance cannot be overstated in achieving optimal results and enhancing overall efficiency in the industry.

Round Knife Cutting Machines:

Round knife cutting machines actively fulfill a crucial role in the garment industry, specifically for cutting curves and circles in fabric. Additionally, these machines employ a rapidly rotating circular blade to precisely cut through fabric layers. Furthermore, they showcase versatility and efficiency, facilitating smooth and accurate cutting across various fabric types. Moreover, round knife cutting machines are purpose-built to handle intricate shapes, making them well-suited for cutting garment patterns and curved sections. Additionally, offering adjustable cutting speeds and blade sizes, they provide flexibility in fabric cutting processes. Ultimately, by significantly boosting productivity, reducing fabric waste, and ensuring precise and consistent cuts, these machines actively contribute to the overall quality and efficiency of garment production.

Band Knife Cutting Machines:

Band knife cutting machines actively serve as indispensable equipment in the garment industry, purpose-built for cutting intricate patterns and complex shapes in fabric. Moreover, these machines employ a continuously moving long, narrow blade to achieve precise and smooth cuts across various fabric types. Additionally, band knife cutting machines excel in handling delicate and stretchy fabrics without causing distortion or fraying. Furthermore, they offer exceptional maneuverability, making them ideal for intricate cuts and curved lines. Moreover, with adjustable cutting speeds and cutting table sizes, they deliver flexibility and efficiency in fabric cutting operations. Ultimately, valued for their accuracy, versatility, and ability to optimize fabric utilization, band knife cutting machines actively contribute to high-quality and cost-effective garment production.

Die Cutting Machines:

Die cutting machines actively serve as a crucial tool in the garment industry for achieving precise and efficient fabric cutting. Moreover, these machines employ a cutting die, typically crafted from metal, to cut fabric into specific shapes and patterns. Additionally, with unrivaled accuracy and consistency, die cutting machines ensure uniformity across garments. Furthermore, they showcase high versatility, facilitating the production of intricate designs and complex shapes. Moreover, by placing fabric on the cutting bed and pressing the cutting die onto it, these machines exert the necessary pressure to create the desired cut. Ultimately, die cutting machines play an essential role in mass production, streamlining the cutting process, reducing labor costs, and enabling faster production cycles in the garment manufacturing workflow.

Laser Cutting Machines:

Laser cutting machines have ushered in a revolution in the garment industry, thanks to their precise and versatile fabric cutting capabilities. Furthermore, these machines harness high-powered lasers to cut through fabric with exceptional accuracy and speed. Moreover, programmable in nature, laser cutting machines enable the creation of intricate patterns and designs in garments. Additionally, they facilitate non-contact cutting, eliminating the risk of fabric distortion or fraying. Moreover, with the ability to cut a wide range of fabric types, including delicate and synthetic materials, laser cutting machines provide unparalleled versatility in garment production. Additionally, they offer the advantage of sealed edges, reducing the need for additional finishing processes. Ultimately, by enhancing efficiency, reducing material waste, and enabling the creation of intricate and high-quality garments, laser cutting machines actively contribute to the advancement of the industry.

CNC Cutting Machines:

CNC (Computer Numerical Control) cutting machines have transformed the garment industry by automating and streamlining the fabric cutting process. Additionally, these machines use computer programming and precise cutting tools to achieve accurate and efficient fabric cutting. Furthermore, CNC cutting machines offer versatility in cutting various fabric types, sizes, and shapes, ensuring consistency in garment production. Moreover, with their advanced software and control systems, they can execute complex cutting patterns with ease. Additionally, CNC cutting machines enable high-speed cutting, reducing production time and improving overall productivity. Furthermore, they also minimize material waste by optimizing fabric utilization. Ultimately, with their precision and automation, CNC cutting machines actively enhance the quality, efficiency, and scalability of garment manufacturing processes.

Sewing Section:

Industrial Sewing Machines:

Industrial sewing machines are the backbone of the garment industry, playing a crucial role in garment construction. These sturdy machines are designed for heavy-duty sewing and high-volume production. They offer a variety of stitch types to meet different sewing needs. With powerful motors and robust frames, they handle thick fabrics and intricate designs. Adjustable speed settings and stitch lengths provide flexibility and precision. Industrial sewing machines are essential for efficient stitching, ensuring garment quality and durability. They are indispensable throughout the manufacturing process.

Overlock Machines:

Overlock machines play a vital role in the garment industry, ensuring neat and professional edge finishing and seam sewing. These specialized machines trim and enclose the fabric edge, preventing fraying and achieving a polished look. They offer various stitch types for versatile seam finishes. With multiple threads and loopers, they sew seams efficiently. Overlock machines are especially valuable for sewing knitted and woven fabrics that need strong and stretchable seams. They enhance production efficiency, improve garment quality, and give a refined appearance to finished products.

Coverstitch Machines:

Coverstitch machines play a crucial role in the garment industry, providing professional and durable hemming and topstitching. These specialized machines create double or triple rows of parallel stitches on fabric, ensuring a secure and decorative finish. They offer various stitch formations, such as plain coverstitch, chainstitch, and decorative topstitching. Coverstitch machines are perfect for hemming garments, attaching bindings, and adding decorative effects. They significantly contribute to the quality and appearance of garments, delivering clean and long-lasting finishes that can withstand regular wear and washing.

Blind Stitch Machines:

Blind stitch machines are important in the garment industry for creating almost invisible hems and stitches. These machines use a special stitch that hides the stitches on the surface. They have adjustable settings for stitch length and tension, ensuring seamless results. Blind stitch machines are commonly used for hemming trousers, skirts, and sleeves, giving them a neat and professional look. They enhance the quality and appearance of garments by providing seamless and durable finishes that add to the overall appeal of the final product.

Buttonhole Machines:

Buttonhole machines are important in the garment industry for creating precise and efficient buttonholes. These machines automate the process, stitching buttonholes with consistent length and shape. They offer different stitch styles like keyhole, round-end, and square-end buttonholes. Buttonhole machines guarantee accuracy and durability, improving the functionality and appearance of garments. They contribute to efficient production, reducing labor costs, and providing a high-quality finishing touch that complements the garment’s overall design.

Button Sewing Machines:

Button sewing machines are essential in the garment industry for attaching buttons efficiently and accurately. These machines automate the process, ensuring precise and secure button placements. They offer adjustable settings for stitch length and tension, accommodating various button sizes and styles. Button sewing machines improve production efficiency, reduce labor costs, and provide professional finishes to garments. They enhance the durability, functionality, and aesthetic appeal of garments, ensuring secure fastenings and elevating the overall quality of the finished products.

Bartack Machines:

Bartack machines play a crucial role in the garment industry for creating strong and reliable stitches, especially for reinforcing garment areas. These machines sew dense and durable stitches, known as bartacks, at specific locations. Bartack stitches strengthen buttonholes, pockets, belt loops, and other critical areas. Bartack machines offer various stitch patterns and lengths, allowing customization for specific garment needs. They provide consistent and precise stitching, ensuring garment longevity and durability. With their high-speed operation and reliability, bartack machines contribute to efficient and high-quality garment production, reinforcing essential areas to withstand wear and tear.

Pressing and Finishing Section:

Steam Irons:

Steam irons are necessary tools in the garment industry for creating smooth and wrinkle-free fabrics. They use steam and heat to eliminate creases and enhance garment appearance. Steam irons have adjustable temperature and steam settings for different fabrics and wrinkles. They improve garment production efficiency and deliver a polished finish. Steam irons enhance garment quality and aesthetics, creating a neat and well-groomed look that meets industry standards.

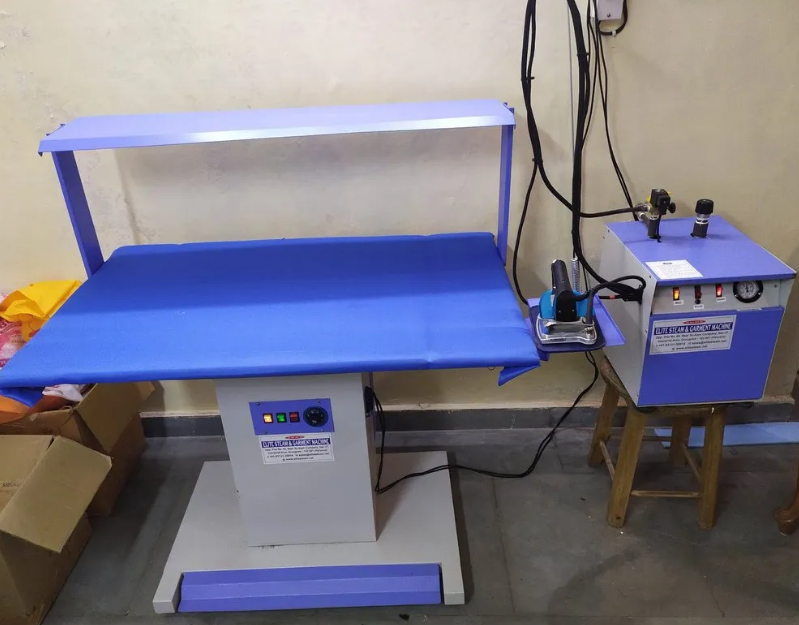

Pressing Machines:

Pressing machines are essential in the garment industry for creating crisp and well-pressed fabrics. They use heat and pressure to smooth out wrinkles and achieve a polished look. These machines have adjustable temperature and pressure settings for different fabrics and garments. They improve garment production efficiency and deliver a neat and professional finish. Pressing machines enhance garment quality and aesthetics, creating a refined and well-groomed appearance that meets industry standards.

Fusing Machines:

Fusing machines are crucial in the garment industry for bonding interlining and fusible materials to fabrics. They use heat and pressure to create a permanent bond between the materials. Fusing machines have heated plates or rollers that activate the adhesive by applying the necessary temperature and pressure. These machines can be adjusted to accommodate different fabric types and weights. By ensuring secure and uniform bonding, fusing machines improve the stability, structure, and durability of garments. They streamline production processes, save time and effort, and enhance the overall quality and professional appearance of garments, ensuring they withstand repeated washing and wear.

Spot Cleaning Machines:

Spot cleaning machines are essential tools in the garment industry for removing stains from garments. They use steam or cleaning solvents to target and treat specific areas, effectively removing stains. Spot cleaning machines have precision nozzles or brushes that deliver the cleaning agent directly to the stained area. They offer adjustable temperature and pressure settings to accommodate different fabrics and stain intensities. These machines quickly and efficiently remove stubborn stains, ensuring garments remain clean and high-quality. By facilitating efficient stain removal, spot cleaning machines contribute to the overall cleanliness and appeal of garments in the production process.

Steam Cabinets:

Steam cabinets are essential equipment in the garment industry for efficiently and effectively steaming garments to remove wrinkles and restore their shape. These cabinets provide a controlled environment where garments are subjected to steam, which helps relax the fabric fibers and eliminate creases. Steam cabinets are designed with adjustable temperature and steam settings to accommodate different fabric types and garment requirements. They feature hanging racks or garment frames to hold multiple garments simultaneously, optimizing the steaming process. Steam cabinets offer a quick and uniform steaming process, ensuring garments are wrinkle-free and ready for further processing or retail display. They contribute to the overall quality and presentation of garments, providing a polished and professional finish.

Thread Trimmers:

In the garment industry, thread trimmers actively serve as essential tools for efficiently and precisely trimming excess thread from sewn garments. Moreover, these specialized machines automatically trim threads after stitching, eliminating the necessity for manual thread trimming. Additionally, featuring sharp blades or rotary cutters, thread trimmers swiftly cut the threads close to the fabric surface. Furthermore, they offer adjustable cutting lengths and speeds, allowing for customization according to garment requirements. Notably, thread trimmers accelerate production cycles, reduce labor costs, and enhance efficiency. Furthermore, they deliver clean and uniform thread trimming, ensuring garments maintain a neat and professional appearance. Ultimately, thread trimmers save time and streamline the overall sewing process, effectively contributing to a more efficient workflow in the garment industry.

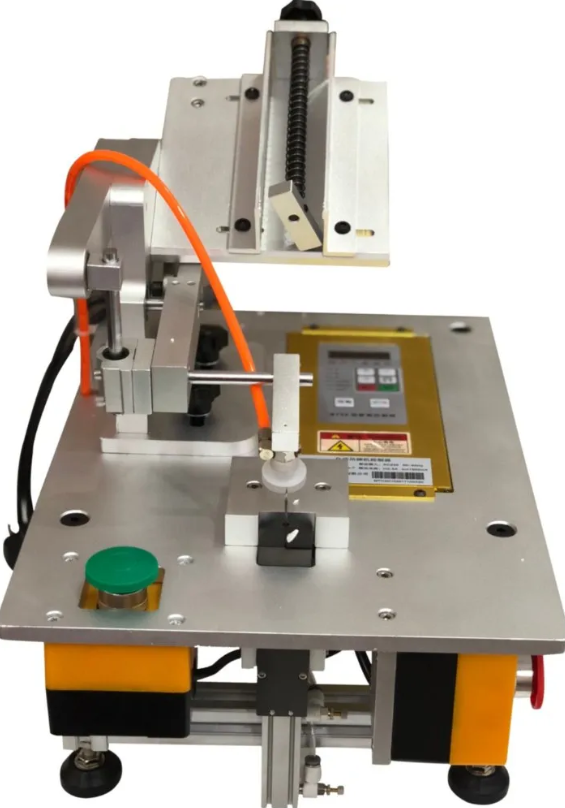

Tagging Machines:

Tagging machines are vital in the garment industry for efficiently attaching tags and labels to finished garments. These specialized machines automate the tagging process, ensuring accurate and secure attachment of product information, pricing, and branding tags. Additionally, tagging machines use either plastic or metal fasteners to affix tags to garments without causing damage. They are designed with adjustable settings to accommodate various tag sizes and thicknesses. Furthermore, tagging machines enhance productivity, reduce labor costs, and ensure consistency in tag placement. Overall, tagging machines contribute to the overall professionalism and marketability of garments by providing a convenient and efficient method for adding essential information and branding elements.

EMBROIDERY PARTS MANUAL:

Embroidery Machines:

In the garment industry, embroidery machines actively serve as indispensable tools for creating intricate and decorative designs on fabrics. Moreover, utilizing computerized technology, these specialized machines stitch intricate patterns, logos, and artwork onto garments with precision. Additionally, the range of design options offered by embroidery machines encompasses different stitch types, colors, and thread thicknesses, allowing for customization and personalization. Furthermore, they accurately replicate complex designs and textures, enhancing the visual appeal and aesthetic value of garments. Moreover, embroidery machines demonstrate high versatility, accommodating various fabric types such as knits, woven fabrics, and even leather. Ultimately, with their ability to create intricate details and contribute to the uniqueness, quality, and branding of garments, embroidery machines play a pivotal role in the fashion industry.

Multi-Head Embroidery Machines:

The garment industry relies on multi-head embroidery machines as essential equipment for efficiently and simultaneously embroidering multiple garments. Notably, these specialized machines incorporate multiple sewing heads, enabling parallel embroidery on several garments at once. Moreover, multi-head embroidery machines surpass single-head machines in productivity and turnaround times. Importantly, they facilitate bulk production of embroidered designs on garments, making them ideal for large-scale manufacturing. Additionally, these machines allow for versatile design placement and offer customization options for each garment. Furthermore, with their advanced technology and synchronized operation, multi-head embroidery machines actively contribute to enhancing the efficiency, quality, and customization of embroidered garments, effectively meeting the demands of the fast-paced fashion industry.

Sequin and Bead Embroidery Machines:

Sequin and bead embroidery machines in the garment industry add glamorous and intricate embellishments to fabrics. Additionally, designers utilize these specialized tools to attach sequins, beads, and other decorative elements onto garments with computer-controlled precision. Moreover, the machines enable the creation of stunning patterns, textures, and effects, offering a wide range of design options. Furthermore, they ensure precise placement of sequins and beads, guaranteeing consistent spacing and alignment. Moreover, the machines enhance productivity and efficiency in embellishment processes with their high-speed operation and automated stitching. Ultimately, sequin and bead embroidery machines contribute to the exquisite detailing and luxurious appeal of garments, infusing the fashion industry with a touch of elegance and sophistication.

These are some of the common industrial garment machines found in the cutting to finishing sections. The garment manufacturing industry offers a wide range of specialized machines to meet various production needs and requirements. We deal in all kinds of industrial machines.